PURホットメルト接着剤 は、湿気硬化技術を活用し、比類のない接着耐久性を実現する反応性ポリマーシステムです。当初は熱可塑性樹脂として塗布されますが、周囲の湿気にさらされると不可逆的な化学架橋反応を起こし、耐久性のある熱硬化性ポリマーネットワークへと変化します。これにより、熱、薬品、可塑剤に対する優れた耐性が得られ、最も要求の厳しい産業用途において優れた引張強度と長期的な信頼性を実現します。

商品番号 :

PUR Adhesive応用 :

Lamination and bonding of wood, plastic, fabric Substrates特集 :

Bond strength and durability, with outstanding resistance to heat, solventsProduct Overview

Runshine New Materials (Foshan) Co., Ltd. provides high-performance polyurethane reactive (PUR) hot-melt adhesives that utilize moisture-curing chemistry to form permanent, cross-linked thermoset networks upon application. These adhesives deliver exceptional bond strength and durability, with outstanding resistance to heat, solvents, and plastics, making them ideal for demanding wood product assembly applications including furniture, cabinetry, flooring, and decorative items. We offer tailored adhesive solutions and comprehensive technical support to ensure optimal bonding performance and reliability for specialized manufacturing needs.

Types Of PUR Hot Melt Adhesive

Product introduction

Our PUR hot melt adhesives deliver superior bonding performance across a wide range of temperatures and substrates, ensuring high initial tack, excellent aging resistance, and reliable operation in both high-speed and challenging environments. Designed for versatility and durability, they provide strong, bubble-free adhesion for laminating, wrapping, edgebanding, and honeycomb panel applications, making them the ideal choice for advanced industrial bonding solutions.

| PUR Hot Melt | |||||||

| Product Category | Mode | Ambient Temp. (°C) | Viscosity | Application Temp. | Open Time /25°C | Key Characteristics | Suitable Substrates |

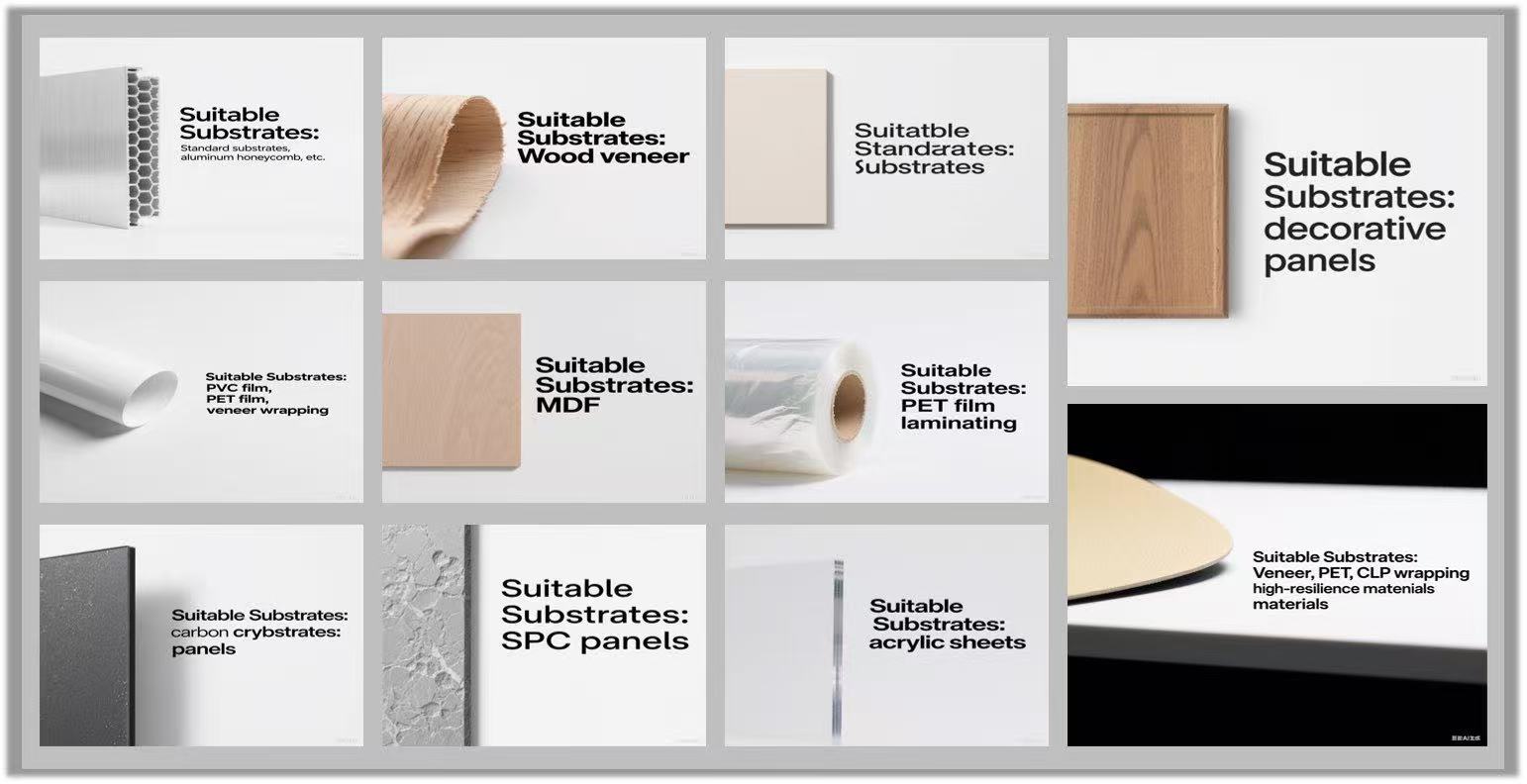

| PUR Flat Laminating Adhesive | YKM8602 | 20-43 | 6000-10000/130℃ | 110℃-140℃ | 8-15 min | Broad compatibility, excellent high-temperature resistance | MDF, decorative panels, acrylic sheets, aluminum panels, SPC panels, carbon crystal panels, etc. |

| YKM8608 | 18-38 | 6000-10000/130℃ | 110℃-140℃ | 4-6 min | Excellent aging resistance, high yield, specifically effective for PET films | Wood veneer, PET film laminating | |

| YKM8607 | 0-23 | 6000-10000/130℃ | 110℃-140℃ | 15-25 min | Superior low-temperature performance, high yield, specifically effective for PET films | Wood veneer, PET film laminating | |

| YKM8611 | 15-35 | 5000-9000/130℃ | 110℃-140℃ | 20-30 min | Broad compatibility, excellent aging resistance, high yield | MDF, decorative panels, acrylic sheets, aluminum panels, SPC panels, carbon crystal panels, etc. | |

| YKM8613 | 25-40 | 5000-9000/130℃ | 110℃-140℃ | 10-20 min | Broad compatibility, excellent aging resistance | MDF, decorative panels, acrylic sheets, aluminum panels, SPC panels, carbon crystal panels, etc. | |

| PUR Edge Wrapping / Banding Adhesive | YKM8722 | 25-43 | 30000-50000/130℃ | 110-140℃ | 90-150 sec | High initial tack, strong adhesion, bubble-free under high temp | Veneer, PET, CLP wrapping on high-resilience materials |

| YKM8723 | 15-35 | 30000-50000/130℃ | 110-140℃ | 40-90 sec /30℃ | High initial tack, wide operating range | Veneer, PET, CPL wrapping,etc. | |

| YKM8724.1 | 30-40 | 30000-50000/130℃ | 110℃-140℃ | 20-60 sec /30℃ | High initial tack, fast positioning, high yield | CPL wrapping | |

| YKM8725.2 | 20-40 | 30000-50000/130℃ | 110℃-140℃ | 60-120 sec | High initial tack, strong adhesion, broad material compatibility | PVC film, PET film, veneer wrapping | |

| YKM8725.3 | 5-25 | 30000-50000/130℃ | 110℃-140℃ | 120-180 sec | Strong adhesion, broad material compatibility | PVC film, PET film wrapping | |

| PUR Edge Bonding Adhesive | YKM8854 | -5-20 | 60000-100000CPS/150℃ | 120℃-160℃ | 60-120 sec | Excellent low-temperature substrate tearing resistance, solves cold temp false tack issue | Standard substrates |

| YKM8856 | 20-45 | 60000-100000CPS/150℃ | 120℃-160℃ | 5-15 sec | High initial tack for summer conditions | Standard substrates | |

| YKM8858 | 20-45 | 60000-100000CPS/150℃ | 120℃-160℃ | 5-15 sec | High initial tack for summer conditions, cost-effective | Standard substrates | |

| YKM8859 | -5-20 | 60000-100000CPS/150℃ | 120℃-160℃ | 1-2 min | Excellent low-temperature substrate tearing resistance, cost-effective | Standard substrates | |

| YKM8861 | 10-35 | 60000-100000CPS/150℃ | 120℃-160℃ | 8-18 sec | High initial tack, wide temperature adaptation range | Standard substrates, aluminum honeycomb,etc. | |

| PUR Honeycomb Panel Adhesive | YKM8861 | 10-35 | 60000-100000CPS/150℃ | 120℃-160℃ | 8-18 sec | High initial tack, wide temperature adaptation range | Honeycomb panels |

| YKM8571 | 10-35 | 40000-80000CPS/150℃ | 120℃-160℃ | 10-20 sec | Excellent substrate tear performance | Honeycomb panels | |

Key Features

PUR Flat Laminating Adhesive

Key Features:

• Excellent High-Temperature Resistance

• Broad Substrate Compatibility

• Superior Aging Resistance

• Moisture-Curing Mechanism

• High Bonding Strength

• Thermal Stability

• Low VOCs

• Rapid Fixture Time

• Resistance to Plasticizer Migration

• Flexibility after Curing

• Chemical Resistance

• Non-Yellowing

• Ease of Machine Processing

PUR Edge Wrapping / Banding Adhesive

Key Features:

• High Initial Tack

• Bubble-Free Bonding

• Excellent Flexibility

• Wide Operating Temperature Range

• Fast Positioning

• Strong Adhesion to Non-Porous Surfaces

• Resistance to High Temperatures

• Moisture-Curing Polyurethane Chemistry

• Suitable for Complex Profiles

• Low Stringing During Application

• Good Wetting Properties

• Durability Under Mechanical Stress

PUR Edge Bonding Adhesive

Key Features:

• Excellent Low-Temperature Performance

• High Initial Tack in Summer Conditions

• Rapid Setting Time

• Strong Tear Resistance

• Cost-Effective Formulation

• Wide Temperature Adaptation Range

• Suitable for High-Speed Applications

• Moisture-Cure Cross-Linking

• Good Gap-Filling Properties

• Resistance to Humidity and Moisture

• Compatibility with Various Edge Materials

• Minimal Shrinkage Upon Curing

PUR Edge Bonding Adhesive

Key Features:

• Excellent Low-Temperature Performance

• High Initial Tack in Summer Conditions

• Rapid Setting Time

• Strong Tear Resistance

• Cost-Effective Formulation

• Wide Temperature Adaptation Range

• Suitable for High-Speed Applications

• Moisture-Cure Cross-Linking

• Good Gap-Filling Properties

• Resistance to Humidity and Moisture

• Compatibility with Various Edge Materials

• Minimal Shrinkage Upon Curing

Applications

Engineered for industrial-grade performance, our PUR adhesives offer exceptional resistance to environmental factors, ensuring long-term structural integrity and reliability in demanding applications.

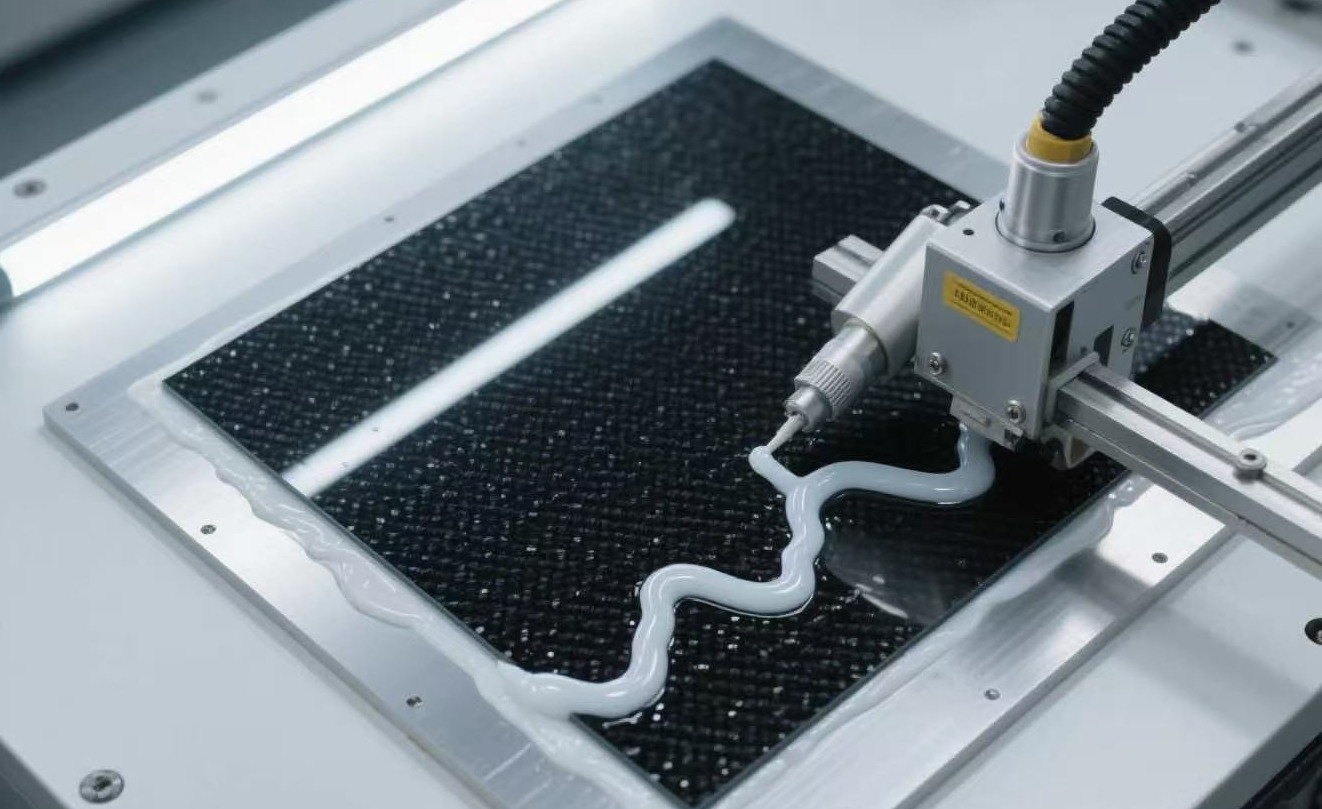

PUR Flat Laminating Adhesive

• Decorative surface lamination on MDF, particleboard, and multi-layer composite panels

• Bonding of high-pressure laminates (HPL), acrylic sheets, and aluminum composite panels

• Furniture and interior decorative panel manufacturing for both residential and commercial use

• Adhesion to SPC (Stone Plastic Composite) and carbon crystal panels in high-end applications

• PET film and wood veneer lamination for aesthetic and protective surface finishing

PUR Edge Wrapping / Banding Adhesive

• Automatic and manual edge banding of furniture, cabinets, and interior décor elements

• PVC, PET, CPL, and veneer wrapping on curved, flat, and profiled edges

• High-resilience material wrapping for automotive and architectural interior trim

• Suitable for both vertical and horizontal wrapping machines across various temperature conditions

PUR Edge Bonding Adhesive

• High-speed edge bonding in panel processing lines for furniture and construction materials

• Sealing and bonding of honeycomb structures and lightweight composite panels

• Low-temperature and high-humidity environment applications without loss of tack strength

• Durable edge sealing for worktops, doors, display panels, and modular furniture systems

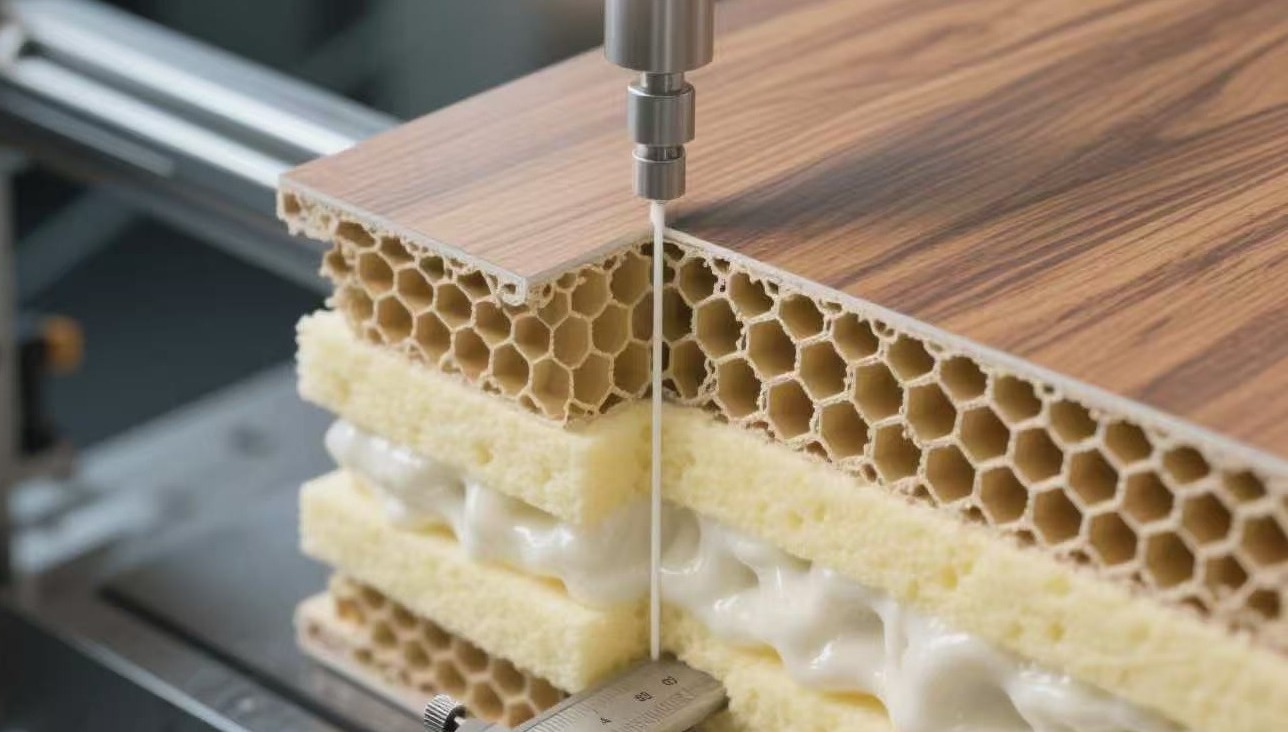

PUR Honeycomb Panel Adhesive

• Structural bonding in aluminum, Nomex, and polypropylene honeycomb core panels

• Fabrication of lightweight composite panels for aviation, marine, and rail transportation interiors

• Sandwich panel production for architectural partitions, doors, and exhibition structures

• High-strength bonding between skins (e.g., aluminum, HPL, glass reinforced plastic) and core material

General Application Instructions for PUR Hot Melt Adhesives

1. Surface Preparation:

The substrate surfaces must be clean, dry, and free from dust, oil, grease, or any other contaminants that could inhibit adhesion. Proper surface preparation is critical to achieving maximum bond strength and long-term durability. For non-porous substrates, light abrasion may be necessary to ensure mechanical interlocking.

2. Adhesive Melting and Application:

The solid adhesive pellets must be melted in a thermostatically controlled, sealed melt tank to prevent premature moisture ingress and degradation. The application temperature must be strictly maintained within the specified range (typically 110-160°C). Temperatures that are too low will result in high viscosity and poor wetting, while excessive heat can cause thermal degradation of the polymer, reducing final bond performance.

3. Open Time and Assembly:

Upon application, the adhesive must be assembled within the specified open time. This is the period when the adhesive remains workable and capable of wetting the second substrate. Assembly must occur before the adhesive forms a skin or cools below its minimum wetting temperature.

4. Pressing and Curing:

Immediate pressure must be applied after assembly to ensure intimate contact between the adhesive and both substrates, and to achieve the desired bond line thickness. The initial bond strength (green strength) is developed upon cooling. The final, ultimate strength is achieved through a chemical cross-linking reaction with ambient moisture. This moisture-curing process forms irreversible urethane bonds, creating a durable, thermoset polymer network. Full cure depends on relative humidity, temperature, and bond line thickness, and may take 24-72 hours to complete.

5. Environmental Considerations:

Application should be conducted in an environment with controlled humidity and temperature. Low humidity will slow the curing reaction, while very high humidity can cause surface foaming. Adequate ventilation is required to manage any minimal isocyanate emissions during application.

Important Safety and Handling Precautions for PUR Hot Melt Adhesives

1. Moisture Sensitivity:

PUR adhesives are highly moisture-sensitive prior to application. The raw material must be stored in its original, sealed container in a cool, dry environment to prevent premature reaction with atmospheric humidity, which will cause gelation and render the product unusable.

2. Thermal Management:

Always melt the adhesive in dedicated, thermostatically controlled equipment. Avoid overheating (exceeding 160°C is not recommended for most products) to prevent thermal degradation, which can lead to a sharp increase in viscosity, discoloration, and the generation of fumes. Do not mix different adhesive types in the same tank.

3. Personal Protection (PPE):

During handling and application, operators must wear appropriate personal protective equipment, including heat-resistant gloves, safety goggles, and long-sleeved clothing to protect against potential thermal burns from hot melt. Ensure adequate ventilation or local exhaust in the application area to avoid inhalation of vapors or aerosols.

4. Isocyanate Awareness:

While cured PUR is inert, the molten adhesive contains reactive isocyanate groups. Avoid generating mists or vapors. Do not allow the adhesive to come into contact with skin or eyes. In case of contact, immediately rinse with plenty of water and seek medical attention if necessary.

5. Equipment Maintenance:

Clean application equipment regularly with specialized PUR cleaning agents before shutdowns to prevent charred residue from clogging hoses and nozzles. Never use water or steam to clean equipment containing molten PUR adhesive.

6. Substrate Compatibility:

Always verify the compatibility of the adhesive with the specific substrates to be bonded, as certain plastics or coatings may be sensitive to the application temperature or the chemistry of the adhesive, leading to substrate deformation or poor adhesion.

7. Curing Conditions:

Achieving full mechanical properties is dependent on moisture-curing. The bond should not be subjected to high mechanical loads or elevated temperatures until sufficient curing has occurred (typically 24-72 hours), which is highly dependent on ambient temperature and humidity.

伝言を残す

スキャンしてWeChatに送信 :

WhatsAppにスキャン :